Nonstick cookware has revolutionized home cooking with its effortless food release and easy cleanup. However, these convenient pans come with specific care instructions that many home chefs overlook. The two cardinal sins of nonstick cookware maintenance – using metal utensils and subjecting empty pans to high heat – can dramatically shorten the lifespan of these kitchen essentials while potentially creating health hazards.

The Silent Killer: Metal Utensils on Nonstick Surfaces

That satisfying clink of metal against pan might signal culinary tradition, but it spells disaster for nonstick coatings. Unlike cast iron or stainless steel, nonstick surfaces feature a delicate polymer matrix designed to create that perfect egg-flipping experience. When metal edges scrape across this surface, they don't just leave visible scratches – they create microscopic tears in the coating that worsen with each use.

Professional chefs often notice home cooks committing this error without realizing the consequences. Those tiny scratches accumulate over time, creating rough patches where food begins to stick. More alarmingly, damaged coating may begin flaking into food at high temperatures. While most modern nonstick coatings are considered food-safe when intact, ingesting flakes of deteriorating coating raises legitimate health concerns.

The physics behind the damage explains why even "gentle" metal tools cause harm. A stainless steel spatula may feel smooth to human touch, but at microscopic levels, its edge resembles a jagged mountain range scraping against the pan's relatively soft surface. Each contact removes minute coating particles, much like sandpaper wearing down wood. This damage occurs regardless of how carefully one uses metal utensils – it's simply a material science mismatch.

Empty Pan Peril: Why Heat Needs a Buffer

Preheating an empty nonstick pan seems harmless – perhaps even logical for achieving perfect searing temperatures. Yet this common practice represents the second major threat to nonstick longevity. Without food or oil to absorb and distribute heat, pan surfaces can rapidly exceed safe temperatures, beginning a chemical breakdown process.

At approximately 500°F (260°C), most nonstick coatings start deteriorating – a temperature easily reached within minutes on high heat settings. The polymer matrix begins breaking down, releasing fumes that can cause flu-like symptoms in humans (a condition nicknamed "Teflon flu") and proving fatal to pet birds with their sensitive respiratory systems. Even before reaching this dramatic stage, repeated overheating causes the coating to lose its nonstick properties through molecular changes.

Restaurant kitchens frequently replace nonstick pans not because of surface scratches, but due to thermal degradation from improper heating. The telltale signs include discoloration (yellowing or browning of the white coating) and a gradual increase in food sticking – both indicating the coating's polymer structure has altered. Unlike visible scratches, this damage occurs at molecular levels before showing visible effects.

The Science of Surface Preservation

Understanding why these two factors cause damage requires examining nonstick technology. Modern coatings typically consist of polytetrafluoroethylene (PTFE) or ceramic-based materials. PTFE relies on an incredibly smooth surface where molecules align to create minimal friction – a perfection that scratches disrupt. Meanwhile, ceramic coatings use silica-based matrices that crack under metal impact and degrade when overheated.

Manufacturers engineer these coatings to withstand normal cooking temperatures when properly used. Food or oil acts as a thermal buffer, preventing localized hot spots and keeping overall temperatures stable. Without this buffer, heat concentrates directly on the coating-substrate interface, accelerating breakdown. Metal utensils compound this by exposing the metal substrate beneath the coating when scratched, creating areas where heat transfers differently.

Practical Solutions for Long-Lasting Performance

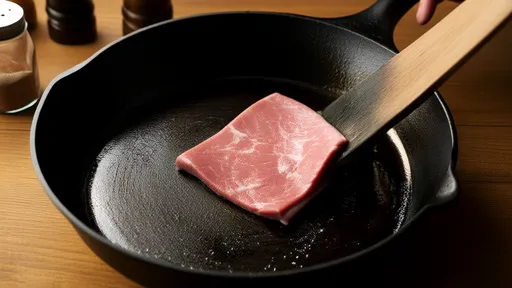

Switching to wood, nylon, or silicone utensils represents the easiest fix for metal-related damage. High-quality silicone tools now offer heat resistance and rigidity approaching metal, without the destructive edges. For those who miss the heft of metal, anodized aluminum utensils provide weight without the sharp edges that damage coatings.

Preheating discipline solves the empty pan problem. Rather than heating pans dry, add a small amount of oil first – it helps distribute heat evenly while providing visual temperature cues. When oil shimmers or flows like water, the pan has reached ideal cooking temperature. For health-conscious cooks using minimal oil, even a few tablespoons of water can serve as a thermal buffer during preheating (removed before adding cooking fat).

Commercial kitchens implement these practices religiously because they understand the economic impact of frequent pan replacement. Home cooks might not notice gradual performance decline until their "nonstick" pan requires excessive oil to prevent sticking – the death knell of a coating's usefulness. By then, the damage has accumulated beyond repair.

Recognizing When to Retire a Pan

Even with perfect care, nonstick coatings don't last forever. Deep scratches that expose the underlying metal, persistent sticking despite proper use, or visible flaking all indicate it's time for replacement. Continuing to use compromised pans risks both cooking performance and potential health effects from coating ingestion.

The investment in quality nonstick cookware pays dividends when paired with proper maintenance. High-end pans often feature more durable coatings and better heat distribution, resisting damage from occasional mistakes. However, no nonstick surface survives repeated metal utensil use or habitual dry heating. Changing these two behaviors dramatically extends pan lifespan, saving money and ensuring safer cooking in the long run.

As cooking technology advances, some newer ceramic and diamond-infused coatings claim greater resistance to these issues. However, the fundamental principles remain – gentle utensils and thermal buffers preserve any nonstick surface. Making these practices habitual ensures cooks get maximum value from their nonstick investment while avoiding potential health concerns associated with coating degradation.

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025